If you’ve been researching roofing repairs or replacements, you’ve probably come across several different roofing materials. The type of materials used for a roof depends on a lot of factors including the structure of the building, the building’s purpose and use, location, budget and local building codes. Two large categories of roofing materials are shingles and membranes. Both of these categories are made up of many different types of products and materials that are used for different purposes, so let’s dive in.

Steep Slope vs. Low Slope

The first factor in determining which of these two roofing methods will be used is whether the roof in question has a steep or low slope. Shingles are typically used on steep slope roofs, while membranes are used in flat or low slope roof situations. For the most part, membrane roofs are seen on industrial and commercial buildings, but can be found on residential properties as well, often as decks, over side and rear adjoining roofs. On residential properties, they are often found over sunrooms, utility rooms, or porches and can be used under decks and other walkable surfaces materials like pavers. Membrane roofs are quite common at waterfront properties and on new construction in the Hampton Roads/Tidewater area.

Types of Membrane Roofs

There are many different roofing membrane products on the market today, each with their own purposes and benefits. Below are four common flat and low slope roof membrane materials.

Thermoplastic polyolefin (TPO)

In the Mid-Atlantic region, TPO is becoming the low slope roofing standard. Because TPO is white, it is highly reflective, which means it’s efficient in keeping buildings cool. In fact, TPO roofs generally exceed the current energy efficiency standards and are a US Department of Energy, Energy Star rated roofing system, which some commercial structures may need to meet. TPO is also very durable thanks to its heat welded seams, and can last 20 to 30 years, making it a budget-conscious choice for businesses.

Ethylene Propylene Diene Terpolymer (EPDM)

EPDM is also a single ply membrane, but it is made of a rubber compound, rather than plastic like TPO. This material has been in commercial use for longer than TPO and has a strong reputation for durability. When properly installed, EPDM can easily last 30 years or more. However, if installed incorrectly or without proper maintenance, the adhesive treated seams can become vulnerable over the long term. Although EPDM roofs are usually black in color, meaning they are not as energy efficient as TPO, the material is 100% recyclable. There are also EPDM products that come in white, doubling their environmentally-friendly factor.

Polyvinyl Chloride (PVC)

PVC is a single ply membrane that is similar in appearance to TPO and is usually white, giving it similar energy efficient qualities. Other environmentally friendly aspects of PVC include its low petroleum content compared to TPO and EPDM. It’s also a recyclable material, even post-consumer, meaning it stays out of landfills. A PVC roofing system requires a slightly greater investment than that of a TPO roof, but it is also very durable and has a similar lifespan if installed and maintained correctly.

Modified Bitumen

The previous materials are almost exclusively used in industrial and commercial structures, but modified bitumen is perhaps the most common material for residential low slope roofs. It consists of five layers of asphalt that has had modifiers added to it to give it plastic or rubber-like properties. It is installed in large rolls and adhered with heat or with a factory applied self-adhesive. Modified Bitumen is designed to withstand very harsh environmental conditions, which makes it a good option for storm and heat prone areas of the Mid-Atlantic such as southeast Virginia.

Types of Shingle Roofs

Shingle roofs are seen on both commercial and residential structures, as long as the roof has a steep slope. There is a wide variety of shingle materials on the market designed for different purposes, styles and locations.

Asphalt Shingles

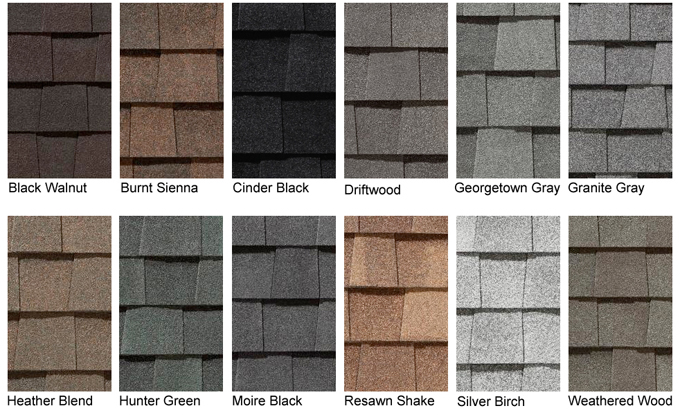

This is the most popular type of residential roofing material today. It’s also the most cost effective. Asphalt shingles consist of a fiberglass mat, top and bottom layers of asphalt, and mineral granules. There are three-tab shingles and architectural shingles, the latter being more costly but also more durable. Asphalt shingles are produced in a wide variety of colors to match myriad home styles and designs.

Synthetic Roofing

Whether they’re made to look like cedar shake, slate or any other type of upscale material, synthetic shingles are made with recycled materials and have a lower impact on the environment in part because of their lifespan which can be 40-60 years. These premium roofing systems should only be installed by roofing contractors who are experienced with these materials. They can be expensive, but their extended lifespan makes up for some of the upfront cost.

Wood Shingles & Shakes

Made from cedar, redwood, southern pine and other woods, these shingles are machine sawn or hand hewn. Some local building codes limit the use of wood shingles and shakes because of concerns about fire resistance, but there are certain wood shingle products that incorporate a factory-applied, fire-resistant treatment. These shingles are not often installed on a new structure or total roof replacement, but because of the age of some homes in the Tidewater region, wood shingles are often needed for repairs of older roofs or to maintain the design of a historic home.

Find an Expert

Whatever type of material you choose for your roof replacement, Andrews Roofing has experience with nearly all of them. If you’re not sure what the best material for your project is, please contact us to set up an appointment with one of our knowledgeable cost estimators. We can help you determine the most appropriate, durable and cost-effective roofing solution for your needs.